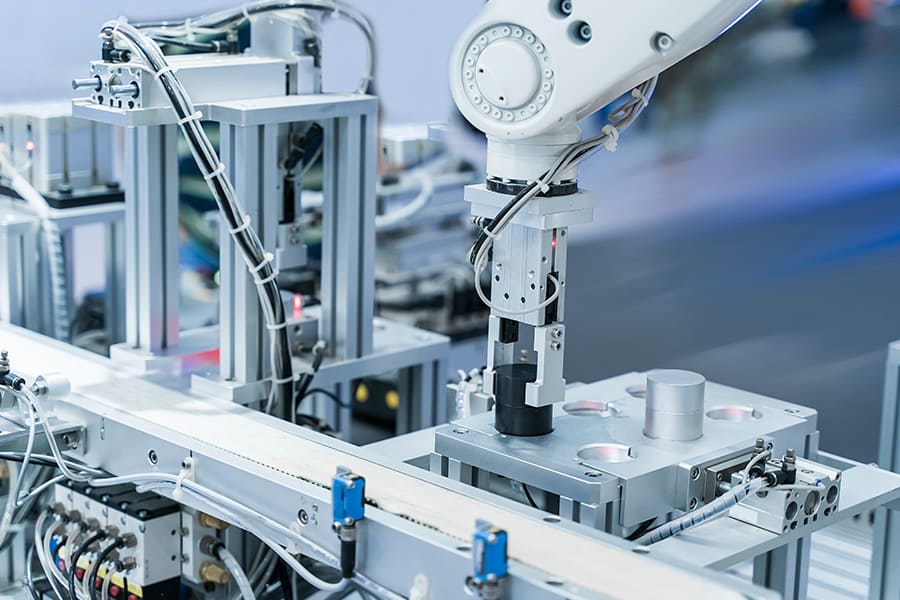

Automatic assembly lines are automated sets of assembly machines, interconnected, for example, by conveyors, that collectively participate in the assembly process. This allows not only individual tasks to be automated, but the entire assembly process, significantly streamlining and speeding up production. Assembly machines, forming part of the assembly line, cooperate with each other, enabling comprehensive automation of the production process.

Advantages of Automatic Assembly Lines:

- Repeatability and Precision: Assembly machines offer high repeatability and precision in task execution, eliminating human errors and improving the quality of the end product.

- Time Optimization: Automatic assembly lines contribute to increased productivity and throughput of the production system, eliminating bottlenecks and accelerating the assembly process.

- Safety and Cost: Eliminating the human factor reduces the risk of errors, improves worker safety, and helps reduce production costs.

Application of Automatic Assembly Lines:

Automatic assembly lines find application in various industries such as the automotive, electronics, food, pharmaceutical, and construction industries. They can perform diverse tasks such as fastening, riveting, welding, or gluing, making them a versatile production solution. Global Automation Sp. z o.o. has produced assembly lines for applications such as assembling car lamps, gearboxes, air filters, and consumer electronics.

Control and Monitoring of the Production Process

By employing advanced monitoring and control systems, automatic assembly lines enable continuous supervision of the production process, resulting in high quality and production continuity. Vision systems and sensors allow effective monitoring of the status and identity of individual components, eliminating the risk of oversights.

Benefits of Investing in Automatic Assembly Lines

Investing in automatic assembly lines brings several benefits, such as speeding up the assembly process, increasing production efficiency, and eliminating human errors. Furthermore, monitoring processes through specially programmed systems allows for continuous quality control and correct production flow, leading to increased company profits.

Through automatic assembly lines, companies can optimize the production process, increase efficiency, and ensure high product quality.