The implementation of the palletization process is a key step in production automation. Utilizing modern palletization solutions enables efficient stacking of products on pallets, eliminating human errors, and improving overall workplace safety.

Our company offers a wide range of comprehensive palletization solutions, individually tailored to the customer’s needs, including Cartesian palletizers, layer palletizers, and robotic palletizing stations.

Additionally, each of the palletizing devices can be equipped with product conveyor systems, pallet warehouses, pallet conveyor systems, and pallet wrappers. The reverse process of palletization is called depalletization.

CARTESIAN PALLETIZER

Our proposal for a Cartesian palletizer provides an innovative and versatile solution dedicated to medium and low outputs. By operating in the XYZ coordinate system and an optional rotational axis of the gripper, our palletizer ensures universality and flexibility. With the appropriate gripper, we can stack a variety of products on pallets, such as boxes, cartons, bags, or jars. The palletizing process can occur individually, in rows, or layers. An additional advantage is the compact design and relatively low investment cost.

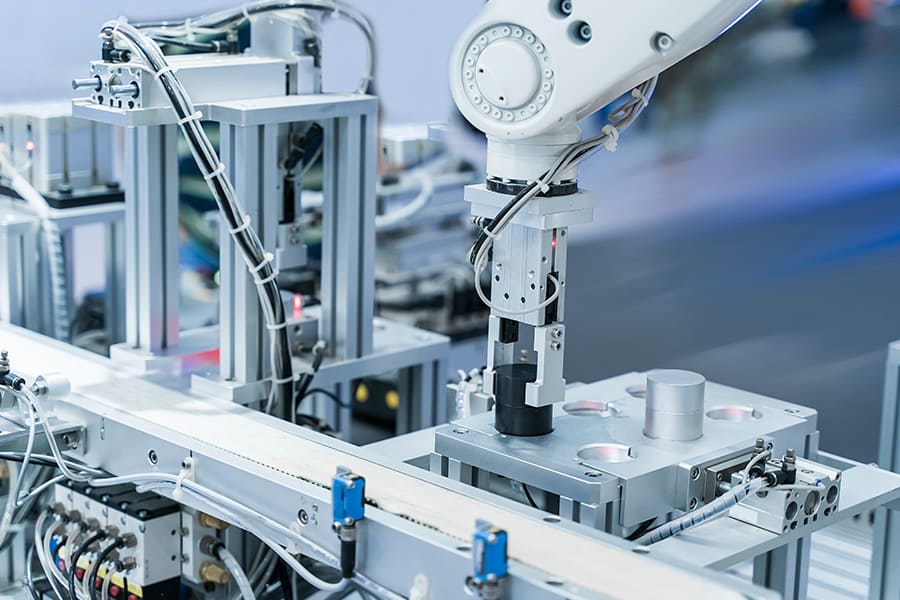

ROBOTIC PALLETIZING STATION

The use of industrial robots provides exceptional versatility, enabling the execution of even the most complex palletizing tasks. The robot can perform various operations in one cycle, such as transferring and stacking products of different shapes, weights, or dimensions, as well as picking products from multiple lines and placing them in various storage locations. Additionally, the station can be equipped with a vision system, allowing work with disordered products and selection. After changing the gripper and program, the robot can be quickly adapted to a completely different task.

BAG PALLETIZER

The specialized bag palletizer provides a dedicated solution for palletizing various types of bags. Collaborating with any bagging machine, the palletizer can be equipped with a conveyor that stacks the material inside the bag. The palletizing process involves retrieving the bag from the conveyor, transferring it to the appropriate height using the gripper, and then placing the bag on the pallet. The device is designed to work with industrial pallets of 1000×1200 and Euro pallets of 1200×800.