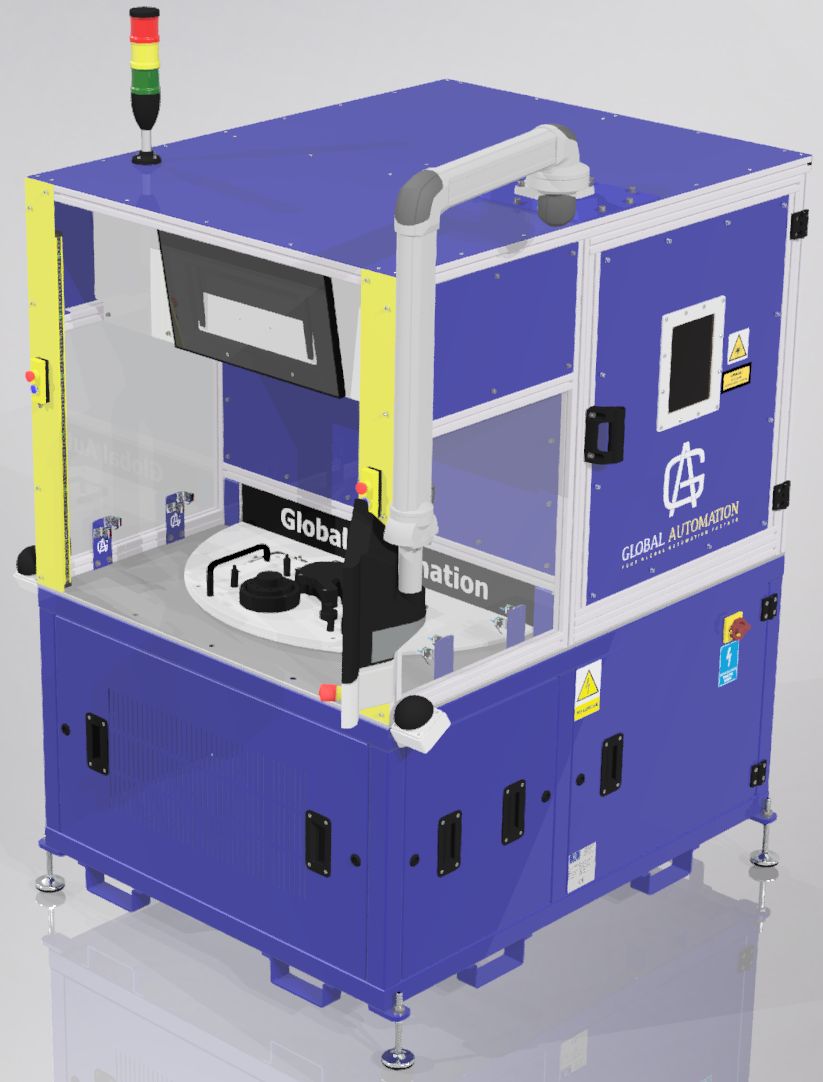

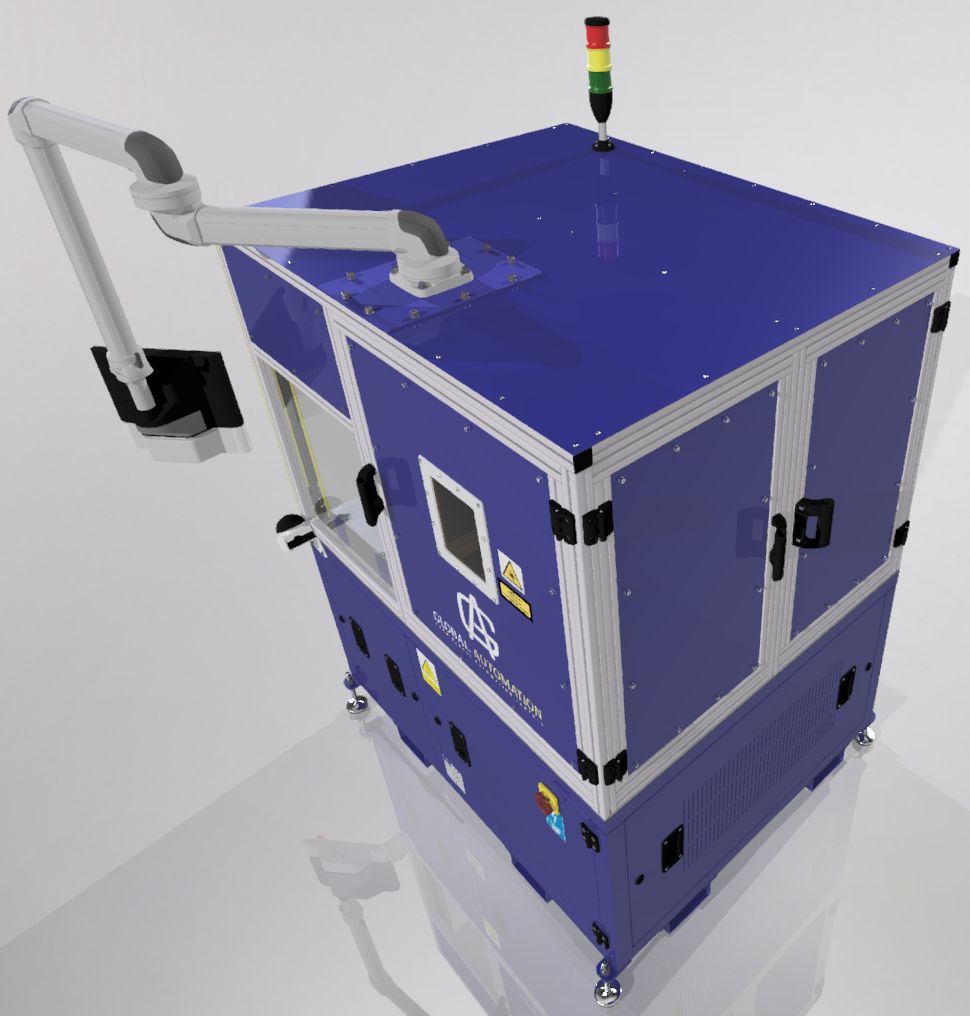

Automated multi-station assembly systems based on a rotary table solution Automated multi-station assembly systems based on a rotary table solution are an innovative solution that enables effective and precise assembly of components using only one operator – depending on the device specifications, it can perform several to several dozen independent stages in a single cycle. The operation is based on the use of a rotary table, which enables the automation of multi-stage assembly. This device finds wide application in the automotive industry, especially in the assembly of complex components such as car headlights, gearbox housings, gearboxes, and advanced electronic systems.

Key Features of the Device

- Multi-station construction allowing simultaneous execution of multiple assembly operations, increasing production efficiency and effectiveness.

- Use of a rotary table for precise positioning of components and facilitating access to different assembly areas.

- Possibility of integration with visual and sensory systems, enabling quality control and component identification.

- Implementation of a traceability system.

Advantages of Purchasing Such a Device

- Increased efficiency and effectiveness of the assembly process through simultaneous execution of multiple operations.

- Improved precision and quality of assembly through the use of a rotary table and integration with visual systems.

- Optimization of the production process by reducing assembly time and increasing production line throughput.

Global Automation Sp. z o.o. has experience in designing and manufacturing advanced automation solutions for the automotive industry. Our extensive experience and innovative approach to automation technology make our automated multi-station assembly systems based on a rotary table solution reliable, precise, and tailored to the most demanding needs of clients, primarily in the automotive sector.