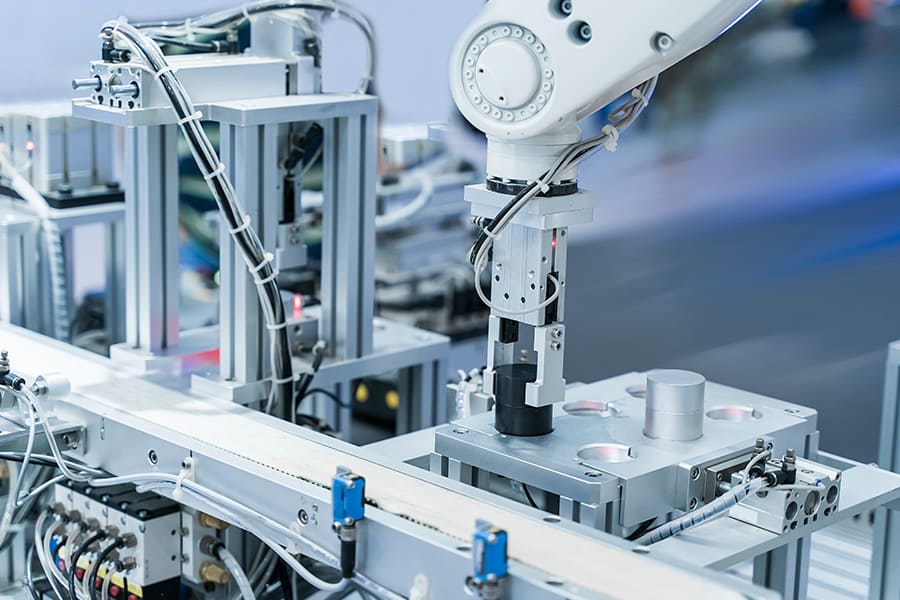

Our counting and packaging lines are designed to meet the individual preferences of the customer and the specific nature of the product. Typically, a counting and packaging line includes a bulk hopper with a feeder, a vibratory bowl, a mini conveyor, counting sensors, and vertical packaging machines. Additionally, there is the possibility of equipping the line with additional components such as indexing conveyors, checkweighers, printers, automatic vibration feeder controller with vibration sensors, and other packaging systems.

The packaging process begins with filling the bulk hopper, from which the items are moved to the vibratory bowls and then transported to the mini linear conveyors. The vibratory bowls are equipped with continuous filling sensors that control the level of their contents. The counting of items takes place at the end of the linear conveyor, where a light curtain is used. The measured items are then packed into plastic bags. Parameters such as bag size, speed of parts dropping into the bag, and type of sealing are adjustable. The filled bags with the measured items can be further transported for the packaging process.

The operation of the line is controlled by advanced PLC controllers from a reputable company, in cooperation with high-quality software. As a result, our packaging lines significantly contribute to optimizing the time required for the correct packaging of small products.