In every company, it is essential to ensure that every carton, box, or pallet is in the right place in the warehouse according to a predetermined schedule. The efficiency of goods and materials flow is a key measure of operational effectiveness. To put theory into practice, it is necessary to employ various techniques of internal storage and transport, which are currently an essential element of market competition.

Without disruptions in the flow of goods or products, it is possible to maximize potential and increase the efficiency of the enterprise. Therefore, internal storage and transport are closely linked, enabling timely deliveries and a chosen assortment for customers. Effective internal transport integrates various production phases, positively impacting the enterprise’s efficiency.

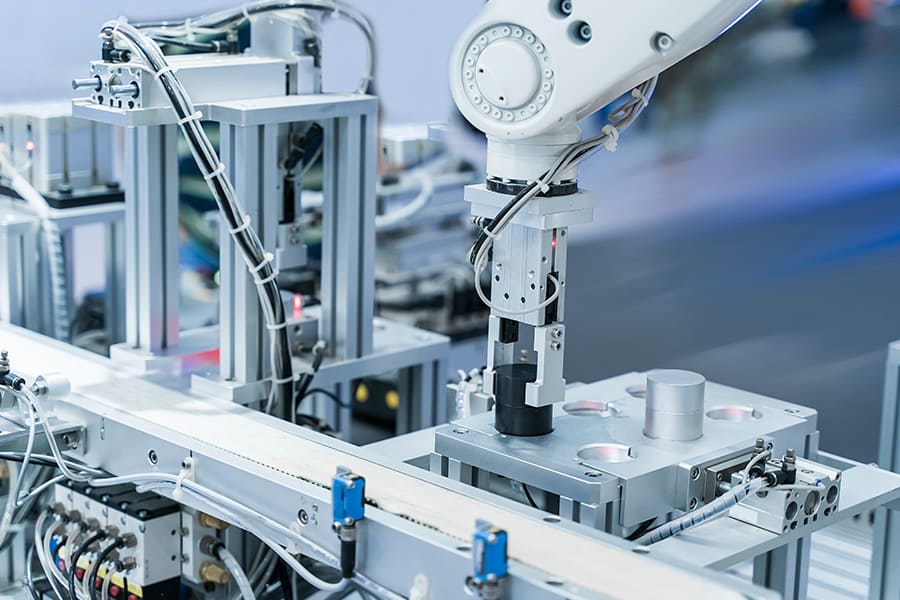

Solutions offered by Global Automation Ltd., based on various types of conveyors and intelligent control, enable the streamlining of internal transport processes. By employing such technologies, it is possible to avoid chaotic movement of materials and goods within the enterprise, which is crucial for optimizing logistical processes.

Belt Conveyors

One of the most common solutions for transporting various materials is the use of belt conveyors. They are characterized by versatility, allowing for the transportation of loads of various sizes at relatively low operating costs. Customers can choose from models equipped with additional elements such as side curtains or cleats, enabling transport both horizontally and at an angle. Our belt conveyors have found application in manufacturing plants across various industries, as well as in sorting facilities and warehouses. Due to their versatility, they can be used as standalone devices or as integral elements of assembly lines. Our products are made from various materials such as:

- PVC,

- polyurethane,

- silicone,

- rubber.

The construction of belt conveyors can be made from various materials such as powder-coated mild steel, stainless steel, or aluminum. Conveyor belts most commonly move on a special steel or polyethylene (PE1000) bed. At the ends of belt conveyors, there are mounted rollers, such as rubber drive roller or electric drum, as well as passive return rollers.

Roller Conveyors

Roller conveyors are solutions for the efficient transport of products with a compact structure and regular base shape, such as pallets, cartons, boxes, or containers. Depending on the application, driven and gravity roller conveyors are distinguished, which find use as assembly stations or end buffers in driven conveyor systems. They also excel in the construction of flow racks in distribution centers, and their design allows for the production of rollers in various lengths, widths, and pitch divisions. Additionally, roller conveyors can be equipped with additional elements such as side guides, end stops, or pneumatic brakes.

Plate Conveyors

Our offering includes the production of plate conveyors based on reputable chain manufacturers. Thanks to our many years of experience in the beverage industry, we are able to design single- and multi-row, straight, and curved plate conveyors, which find application in various industries such as food, cosmetic, pharmaceutical, electrical, electronic, automotive, and paper.

Modular Conveyors

Conveyors based on modular belts provide an effective solution for transporting various products of varying mass. Their versatility comes from the possibility of equipping them with cleats and side curtains, enabling their use for both horizontal and inclined transport. With various types of modular mats serving as the conveyor base, they can be effectively utilized in many industries. Each belt is carefully tailored to the individual needs of the customer and the characteristics of the transported products.

The construction of modular conveyors is based on profiles made of stainless steel, aluminum, or powder-coated black steel. Modular belts, serving as the conveyor base, are carefully selected for specific applications, guaranteeing reliability and long service life of the transport lines. The key advantages of modular conveyors include high belt strength, the ability to customize the belt for working conditions, longitudinal and transverse cleat arrangements, cost and downtime reduction through the replacement of damaged parts, easy maintenance, and a variety of modular elements providing a wide range of conveyor applications. To secure the transported element from falling off the conveyor, side bands attached to the load-bearing structure or profiled plastic sliding strips, also acting as a guide for the belt, are used.